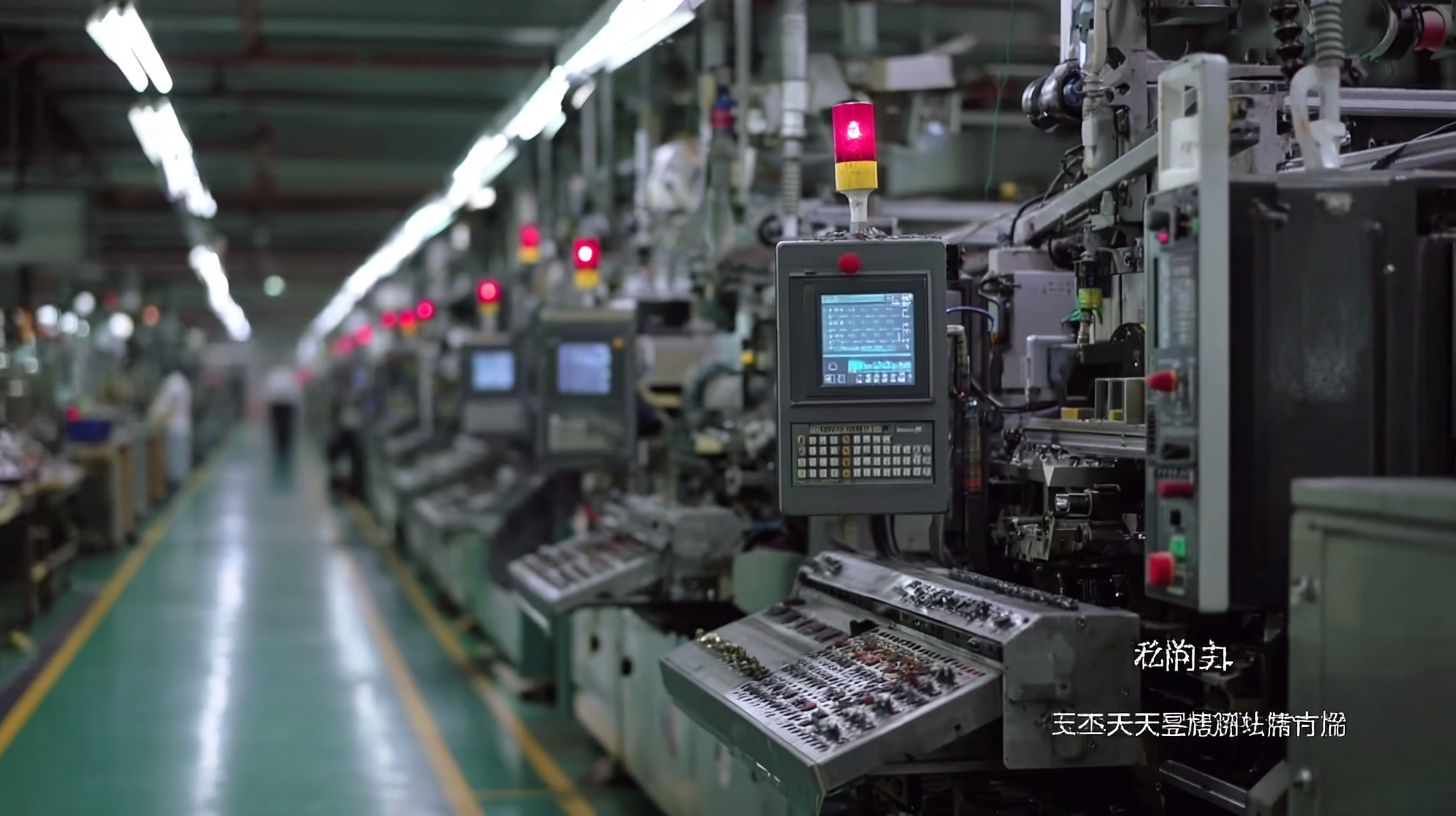

In today's highly competitive global marketplace, the unmatched quality of Chinese manufacturing has garnered the trust of manufacturers and consumers alike. As industries across the world increasingly rely on China's production capabilities, understanding the factors that contribute to this exceptional standard becomes essential. This ultimate guide delves into the intricate processes, innovative technologies, and stringent quality controls that define Chinese manufacturers.

From electronics to textiles, Chinese factories leverage advanced machinery and a skilled workforce to deliver products that meet international standards. By exploring this topic, we aim to provide insights that highlight how Chinese manufacturing not only meets but often exceeds the expectations of global markets, ensuring a reliable supply chain for businesses around the world.

The evolution of Chinese manufacturing has been nothing short of remarkable, transforming from a local industrial base to a global leader in just a few decades. According to a report by McKinsey, China's manufacturing output reached $3.6 trillion in 2020, accounting for nearly 30% of the world’s total manufacturing value. This rapid growth has been supported by substantial investments in technology and innovation, helping Chinese manufacturers to shift from low-cost production to high-quality, advanced manufacturing processes.

One key factor driving this transformation is the adoption of automation and smart manufacturing techniques. The China Manufacturing 2025 initiative aims to upgrade the country’s manufacturing capabilities, emphasizing robotics, AI, and the Internet of Things (IoT). As a result, manufacturers are enhancing efficiency, reducing costs, and improving product quality, which builds trust among global markets.

Tip: Companies looking to collaborate with Chinese manufacturers should prioritize suppliers that demonstrate a commitment to quality control and sustainability practices.

The shift towards sustainability is also notable, with many manufacturers embracing green technologies and practices. According to the 2021 PwC Global Manufacturing Survey, 73% of respondents indicated that their organizations are integrating sustainability into their manufacturing processes.

Tip: When selecting partners in China, consider those who not only meet production demands but also invest in eco-friendly practices to ensure long-term viability.

Chinese manufacturing has gained an unparalleled reputation for quality and reliability, firmly establishing itself as a cornerstone of global supply chains. Several key industries are at the forefront of this manufacturing excellence. The electronics sector, for instance, is a powerhouse, with companies producing everything from smartphones to advanced semiconductor components. This rapid technological advancement is supported by innovations in automation and quality control processes, ensuring that products meet rigorous international standards.

Another driving force behind Chinese manufacturing is the textile and apparel industry. With a strong emphasis on craftsmanship and efficiency, Chinese factories are able to produce high-quality garments at competitive prices. Brands looking to source materials and finished goods often find China to be the ideal partner, as it offers a unique blend of tradition and modern techniques.

**Tips:** When exploring partnerships with Chinese manufacturers, it’s important to conduct thorough research on their production capabilities and quality control measures. Additionally, maintaining clear communication about expectations can significantly enhance collaboration. Establishing a strong relationship built on trust will pave the way for successful long-term partnerships.

Chinese manufacturing has gained a reputation for unmatched quality, primarily due to its rigorous quality control measures and adherence to global standards. Manufacturers in China employ a systematic approach to quality assurance, incorporating advanced technologies and methodologies such as Six Sigma and Total Quality Management. These frameworks help identify potential defects and streamline production processes, ultimately resulting in high-quality products that meet international expectations.

Moreover, Chinese manufacturers often collaborate closely with international partners to understand and implement specific quality requirements. This includes compliance with ISO certifications and industry-specific standards, ensuring that products not only meet quality benchmarks but also cater to the changing demands of global markets. Regular audits and inspections are integral to the process, enabling manufacturers to maintain transparency and accountability. This commitment to quality control not only enhances the reputation of Chinese products but also builds trust with clients around the world, solidifying China’s status as a leader in the manufacturing sector.

| Dimension | Description | Quality Control Method | Standard Compliance |

|---|---|---|---|

| Raw Material Quality | Use of high-grade materials sourced from verified suppliers | Incoming Material Inspections | ISO 9001, ASTM Standards |

| Production Process | Adoption of advanced machinery and skilled workforce | Process Audits and Control Charts | ISO 14001, Six Sigma |

| Final Product Inspection | Comprehensive inspection before shipping | Random Sampling and Testing | CE, RoHS Compliance |

| Supplier Evaluation | Regular evaluation of supplier capabilities and quality | Supplier Audits | TQM Principles |

| Customer Feedback | Collecting and analyzing customer feedback for continuous improvement | Customer Satisfaction Surveys | Customer Service Standards |

The landscape of Chinese manufacturing is undergoing a profound transformation, driven by innovative technologies that are reshaping production processes and improving efficiency. Automation, artificial intelligence, and the Internet of Things (IoT) are being seamlessly integrated into manufacturing lines, allowing for real-time data analysis and enhanced decision-making capabilities. These advancements not only streamline operations but also significantly reduce production costs, enabling Chinese manufacturers to offer competitive prices globally.

Moreover, the adoption of cutting-edge technologies such as 3D printing and robotics is fostering a new era of customization and flexibility in Chinese manufacturing. Companies are increasingly able to produce tailored products that meet specific customer needs, thus enhancing their market appeal. As these innovations continue to evolve, they position China as a leader in manufacturing excellence, attracting investment and partnerships from around the world. This commitment to technological advancement solidifies the trust that global markets place in Chinese manufacturing, reinforcing its reputation for unmatched quality and reliability.

In the evolving landscape of global trade, the significance of trust in manufacturing partnerships cannot be overstated, particularly in relation to Chinese manufacturing. As countries navigate the complexities of tariffs and trade policies, such as those introduced by the recent U.S. administration, the need for reliable and high-quality suppliers becomes paramount. The initiatives to bolster domestic manufacturing in the U.S. reflect an effort to reduce trade deficits, yet they risk unsettling longstanding global trust in the American market. This is where Chinese manufacturers shine, showcasing unmatched quality and innovation, even in the face of geopolitical tensions.

As China emerges as a leader in advanced industries, its capacity for innovation is increasingly recognized worldwide. Global partnerships are being forged based on this trust, particularly in sectors like green technology where collaboration is essential for sustainable development. Countries benefiting from China-IFAD initiatives illustrate how knowledge and resource mobilization from the Global South can address pressing issues like rural poverty. In this context, Chinese manufacturing solutions are not only trusted but are strategically positioned to lead in building a resilient and trustworthy global trade environment.